SPINDLE DRIVEN

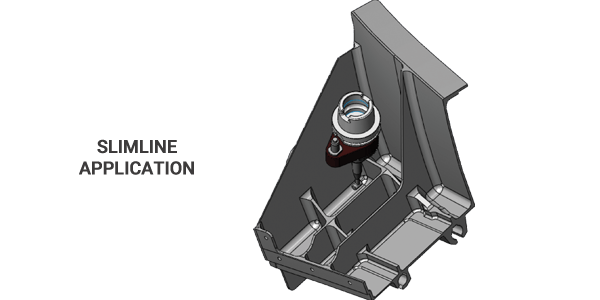

Slimline heads are driven by the machine spindle and have smaller dimensions compared to standard heads for machining parts with limited access.

Slimline angle heads from Alberti facilitate unmatched precision when machining parts with limited access and demanding complexity. A wide variety of high speed (up to 15,000 rpm) micro machining NSK front end attachments are available as well as various extensions.

Get a Quote

Slimline heads are driven by the machine spindle and have smaller dimensions compared to standard heads for machining parts with limited access.

Slimline heads are mainly used for small machining such as drilling, milling & deburring that require small dimension tools and high RPM.

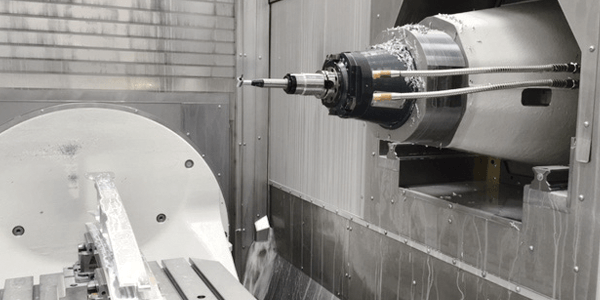

Increased thermal stability and rigidity compared to materials such as steel and aluminum. Bearing housing surfaces are completely ground.

Special composition low friction seals reduce heat build up and keep contaminants out. High pressure rotary joint allows up to 100 Bar Coolant Pressure.

One piece flange arm and pins grants increased rigidity and stability to the whole structure while machining. Ultra precise pitch dimension.

Solid piece spindle made out of hardened steel to increase resistance to bending stress by up to 25%. Achieve higher RPM without vibrations.

Gears are made out of special hardened super alloy. They are completely ground and treated with isotropic polishing that results in a dramatic reduction of vibrations and friction.

Super precise ABEC 7 and 9 Class Bearings. They ensure perfect concentricity and stability during machining.