TORQUE TRANSFER

The Tsudakoma dual leading gearing system features the largest tooth engagement of any rotary table manufacturer. This Generates up to 85% torque transfer efficiency.

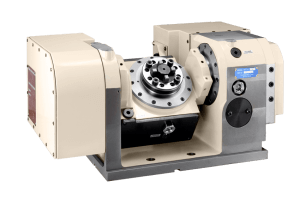

For five axis machining, the RTT with its pallet system allows for unprecedented access (five sides) to the part. Parts that are held with vises, chucks, and clamps limit the access (up to four sides), thus decreasing the efficiency of the process. Because the RTT turns on center, shorter tools and less spindle travel is required. The uniqueness of the pallet system also creates a lower profile than parts that are held with vises, chucks, and clamps thus increases the rigidity. Two pneumatic rotary joints on the rotary axis allow automated clamping/un-clamping of a number of chuck & pallet system.

Get a Quote

The Tsudakoma dual leading gearing system features the largest tooth engagement of any rotary table manufacturer. This Generates up to 85% torque transfer efficiency.

Tsudakoma uses proprietary high tensile strength brass to build the gears. This enables exceptionally smooth cutting due to the inherent lubricating properties.

The Tsudakoma worm wheel uses an oversize diameter pitch circle resulting in reduced pressure on the contact surface compared to a conventional gearing system.

Tsudakoma utilizes full tooth depth engagement with a larger gear module resulting in a larger surface area yielding a substantially stronger worm gear system.

All Tsudakoma rotary tables and indexers use ultra-precision cross roller bearings. Four times more rigid than angular contact bearings.

Koma Precision, Inc. provides comprehensive rotary table selection assistance. Torque calculations, interference drawings and 3D models are value added services offered by us.