Koma Precision now offers laser calibration for multi-axis mills and lathes.

Our technicians have years of experience and use top-tier equipment to provide the most precise machine tool diagnostics and calibration available.

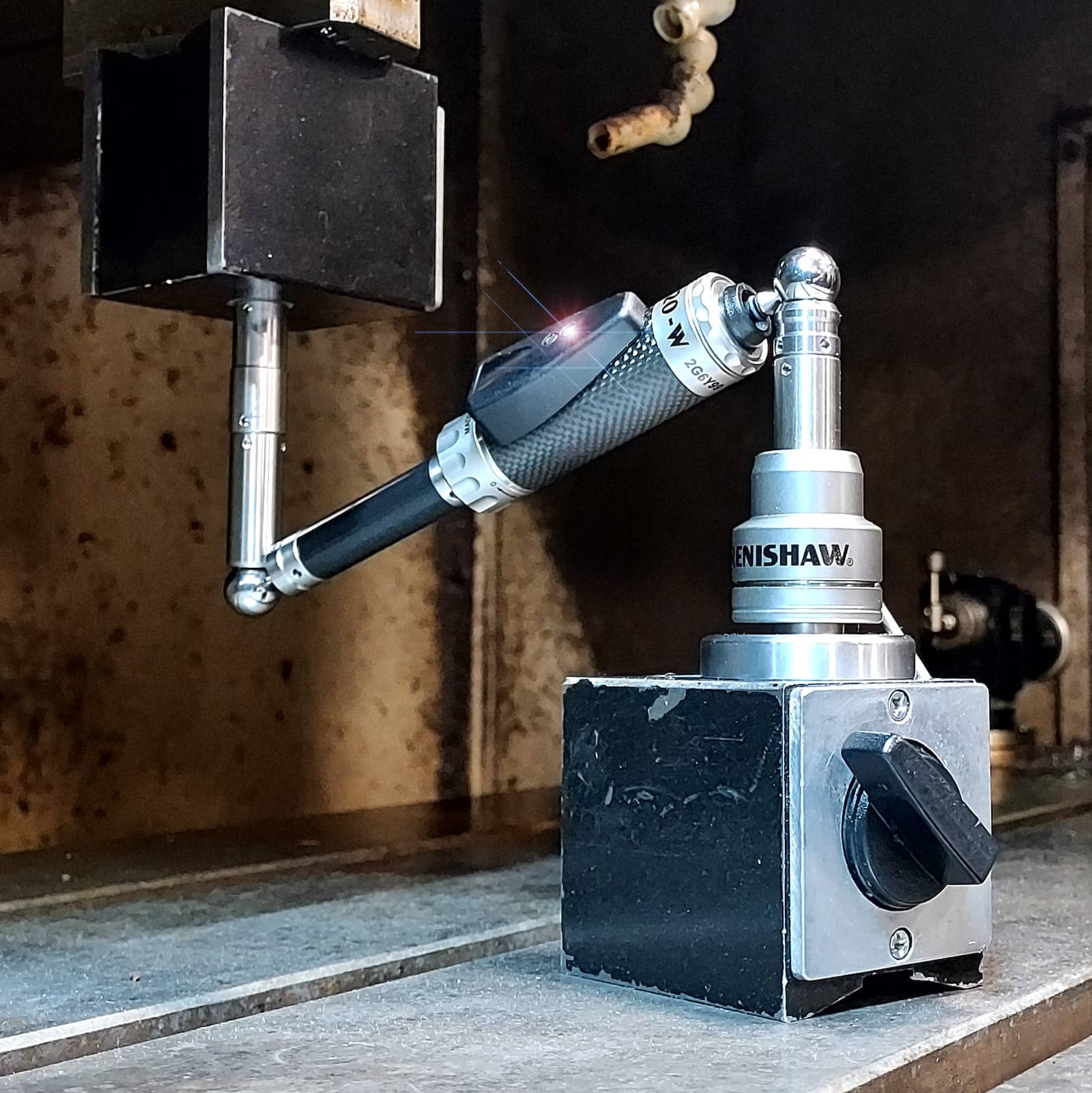

We also offer fast, practical ballbar testing to assess machine performance. A ballbar test either before or after calibration shows the resulting circularity of the axes, including identifying the components that affect circularity. A great diagnostic tool to ensure that your machine is performing as it should.