HI FLEX

For over 35 years, Alberti has been providing the most innovative range of products that are extremely reliable and enable manufacturing to strict tolerances.

The designing and manufacturing stage of all Alberti angle heads - either standard or customized - start in the engineering department which is responsible for product concept, design and development.

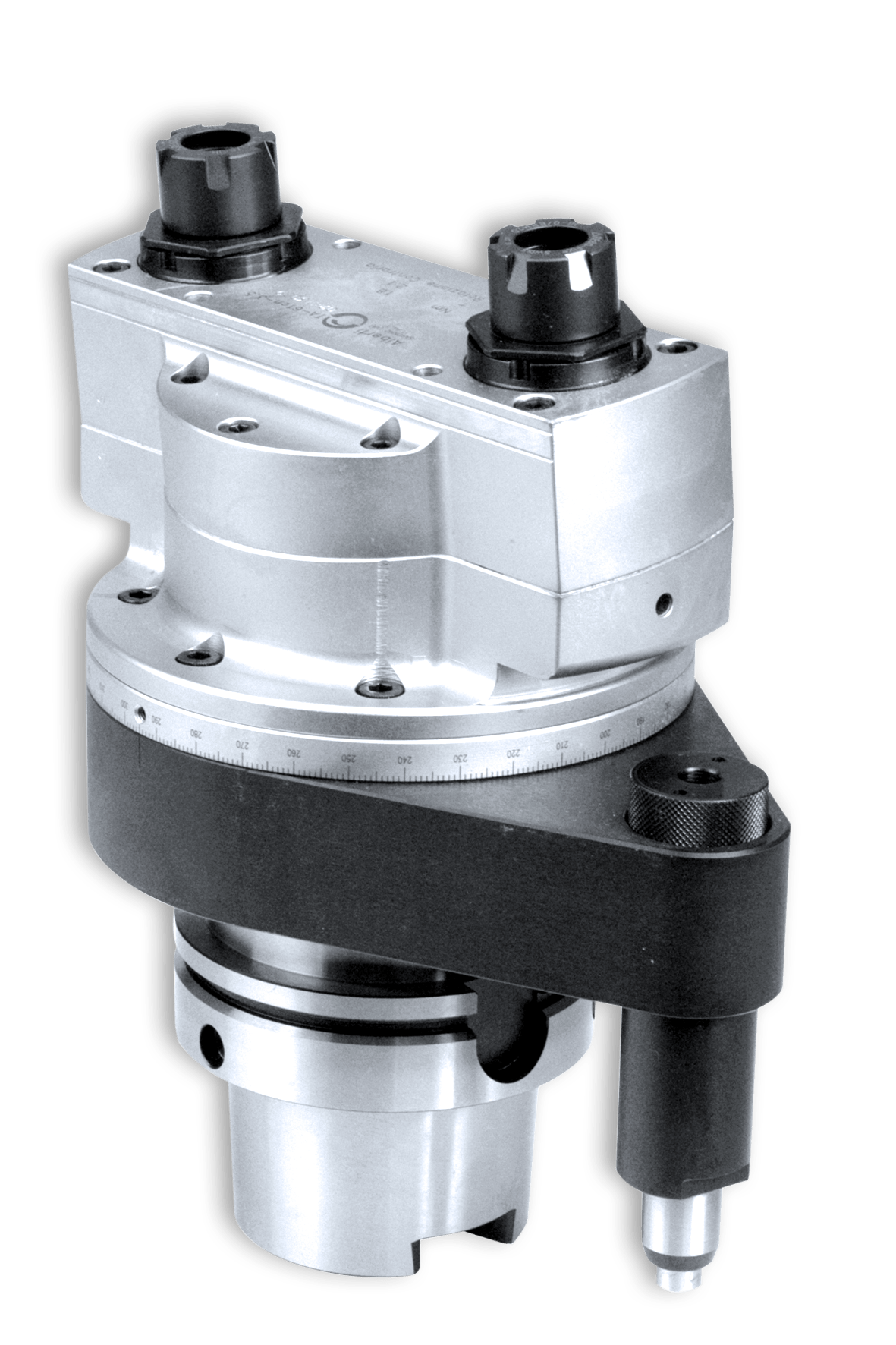

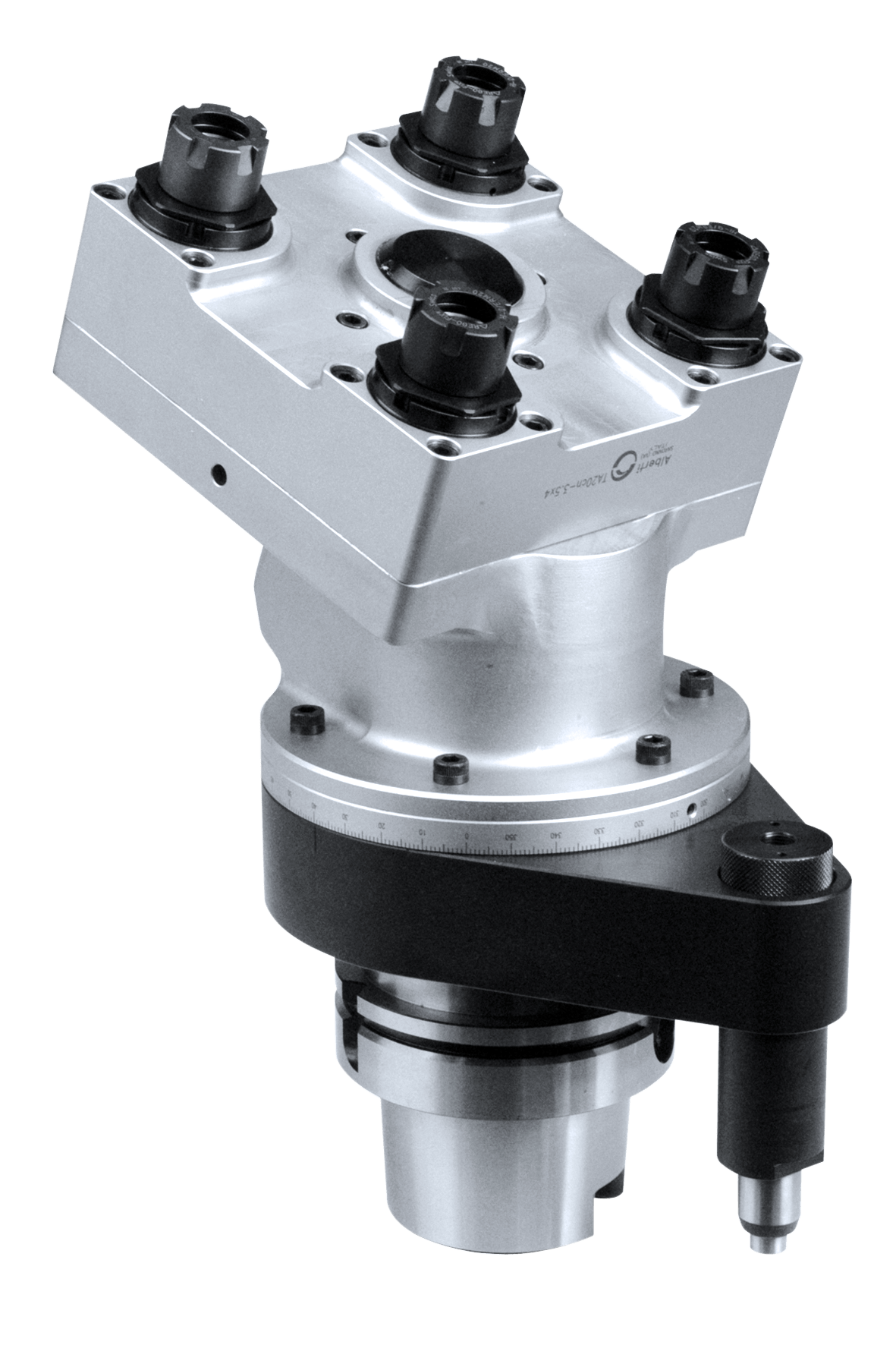

Custom designed angle heads and stationary tools from Koma Precision represent the state of the art in ultra precision, application specific tooling. Tools are designed to facilitate unmatched precision when machining parts with demanding complexity. Specialty angle heads, multi-spindle tooling and stationary multi-spindle heads have been designed incorporating up to 252 spindles for a complete range of machining centers, as well as OEM specialty machinery.

Get a Quote

For over 35 years, Alberti has been providing the most innovative range of products that are extremely reliable and enable manufacturing to strict tolerances.

Fixed angle heads, offset angle heads, multiple output heads, long reach angle heads are just a few examples of Alberti’s design and manufacturing capabilities.

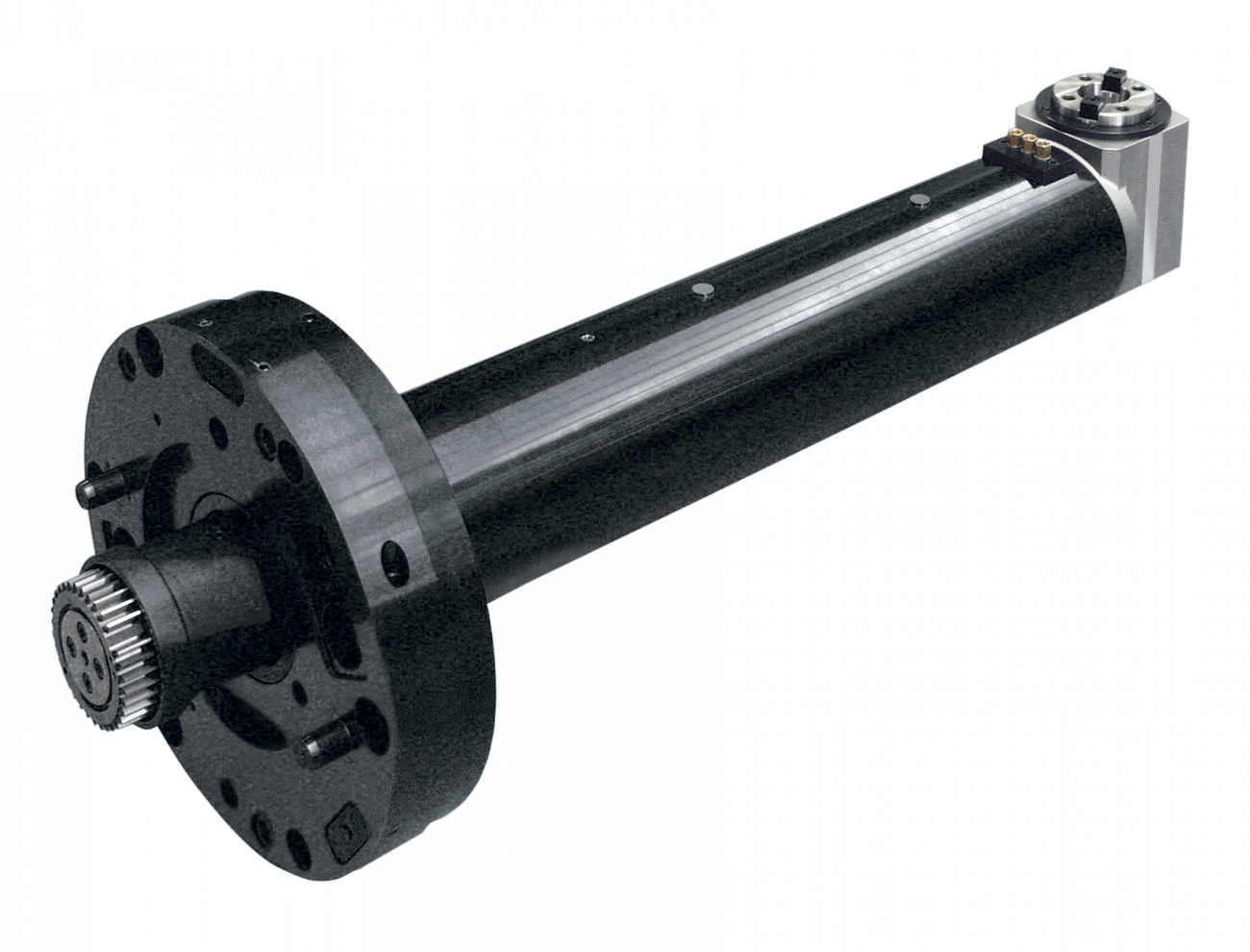

Increased thermal stability and rigidity compared to materials such as steel and aluminum. Bearing housing surfaces are completely ground.

Special composition low friction seals reduce heat build up and keep contaminants out. High pressure rotary joint allows up to 100 Bar Coolant Pressure.

Gears are made out of special hardened super alloy. They are completely ground and treated with isotropic polishing that results in a dramatic reduction of vibrations and friction.

Solid piece spindle made out of hardened steel to increase resistance to bending stress by up to 25%. Achieve higher RPM without vibrations

One piece flange arm and pins grants increased rigidity and stability to the whole structure while machining. Ultra precise pitch dimension.

Super precise ABEC 7 and 9 Class Bearings. They ensure perfect concentricity and stability during machining.