ERGONOMICALLY DESIGNED

The Performance presetter was designed with an ergonomic micrometric hand wheel allowing for easy fine adjustment of the presetter’s optics. A “zero gravity” support column allows smooth, effortless movement of the camera optics in both X and Z.

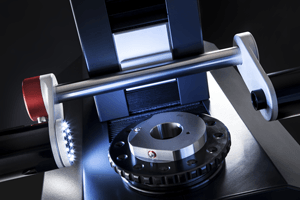

TOOL HOLDERS

High precision, interchangeable spindle pots allow a guaranteed maximum of ±2 microns of run-out. A built-in calibration system eliminates the need for an extra calibration gauge, and allows for fast and precise set up.

SOFTWARE

CVS software is easy to use, & all functions are easy to find using simple graphical icons. It has never been easier or faster to set your tooling. Create tool lists and generate tool offsets in minutes with the CVS software. New DXF software allows the user to easily compare tool profiles or create and export new tool profiles.

CONSTANT GEOMETRY TECHNOLOGY

Material choice is at the heart of Constant Geometry Technology. Using only like materials with an identical thermal expansion coefficient, we can guarantee constant presetter geometry in all working conditions.

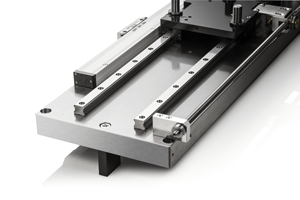

SLIDES & GUIDEWAYS

The Performance is built with dual SP Precision guides and preloaded recirculating bearings mounted to a stabilized steel base ground to 2 microns of planarity. 1-micron glass optical scales are used to ensure the highest accuracy of tool measurements.

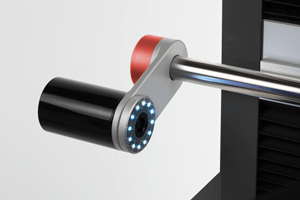

VIEWING SYSTEM

Easy to use software combined with a full HD 24” monitor provides the operator with full control. Easily select any of the presetters measuring options with one click while still viewing the edge of the cutting tool. The telecentric lenses on the HD camera provide a full field of vision.