TORQUE TRANSFER

The Tsudakoma dual leading gearing system features the largest tooth engagement of any rotary table manufacturer. This Generates up to 85% torque transfer efficiency.

Tsudakoma specialty rotary tables are the result of a collaboration between the engineering staffs of Tsudakoma, KOMA Precision, and the OEM/end user. Features typical of specialized tables include multi-port rotary joints, robotically controlled clamping surfaces, automated part detection, and custom fixturing, custom workholding and part clamping fixtures. Encoder and scale feedback for increased accuracy. Specialty rotary tables generate significantly reduced part costs and substantial improvements in accuracy and throughput.

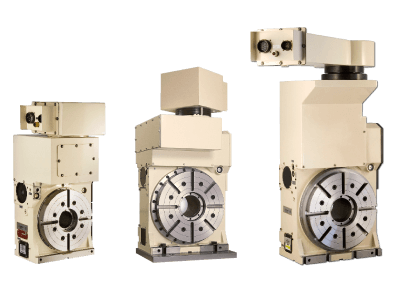

Pictured are RWB-250K, RWB-320K, and RWB-400K rotary tables each equipped with custom designed swivel boxes or swivel arms to facilitate cable management on a pallet equipped horizontal machining center.

Get a Quote

The Tsudakoma dual leading gearing system features the largest tooth engagement of any rotary table manufacturer. This Generates up to 85% torque transfer efficiency.

Tsudakoma uses proprietary high tensile strength brass to build the gears. This enables exceptionally smooth cutting due to the inherent lubricating properties.

The Tsudakoma worm wheel uses an oversize diameter pitch circle resulting in reduced pressure on the contact surface compared to a conventional gearing system.

Tsudakoma utilizes full tooth depth engagement with a larger gear module resulting in a larger surface area yielding a substantially stronger worm gear system.

All Tsudakoma rotary tables and indexers use ultra-precision cross roller bearings. Four times more rigid than angular contact bearings.

Koma Precision, Inc. provides comprehensive rotary table selection assistance. Torque calculations, interference drawings and 3D models are value added services offered by us.